Environment

Scroll to discover

Scroll to discover

Ardagh Metal Packaging (AMP) is one of the leading producers of aluminium beverage cans, the world’s most recycled drinks packaging. Made from a durable metal that can be reprocessed with minimal losses, our products can play a key role in a more circular economy, reducing environmental pollution and avoiding emissions.

As a manufacturer with a complex supply chain and present in multiple locations, we work to achieve the best environmental performance possible. We are committed to identifying, measuring and improving outcomes in all aspects of our value chain – from the energy we procure, to the sources of our aluminium and the ways that our products are collected and recycled.

Our focus is on reducing energy consumption and emissions while maximising recycling rates and optimising materials’ usage. We also place great importance on responsible waste management, avoiding landfill usage and striving to minimise water consumption wherever possible.

We have implemented robust environmental management systems across all our sites and focus on continual improvement. Our strategy is to reduce consumption and enhance efficiencies while investing in innovative technologies that minimise emissions. In addition, we collaborate closely with our suppliers to advance low-carbon aluminium technologies and invest in renewable energy solutions, helping to reduce our Scope 1, 2 and 3 emissions.

The Ecology pillar of our sustainability strategy focuses on reducing waste and water consumption, minimising our environmental impacts and contributing to a more sustainable future.

Around the world, despite the availability of recycling technologies, approximately 80% of waste is still being sent to landfills. The negative impact this is having on ecosystems and GHG emissions is severe. At AMP, we strive to reduce the amount of waste we generate through our operations. And, through reuse and recycling, we aim to prevent our packaging and waste materials ending up in landfills. When reuse or recycling is not possible, we apply controls and treatment technologies to prevent human health effects and to minimise the environmental impacts of disposal.

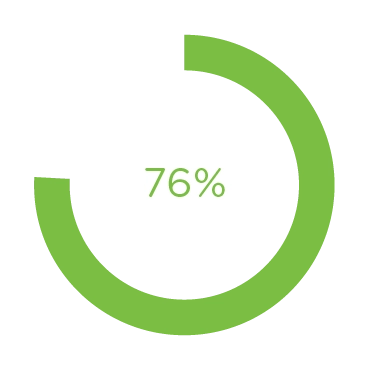

Recycled Waste

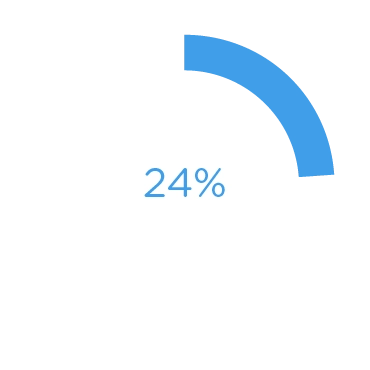

Disposed Waste

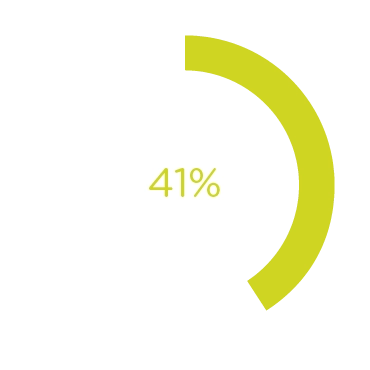

Share of Hazardous Waste

*All of our data has been Third-Party Assured (limited assurance). To see our Independent Assurance Statement, click here: AMP-Independent-Assurance-Statement-2024

Fresh water, a finite resource, is strategically critical for our business. With scarcity increasingly impacting regions around the world, our commitment to reducing water usage across global operations is central to our sustainability efforts. Water plays a key role in various stages of our manufacturing processes, including forming, washing, rinsing, and cooling beverage cans. It is also vital in aluminium production and in the creation of beverages made by our customers. Although AMP’s facilities require freshwater inputs, most of the water used is returned to the water system, with zero water remaining in our final products.

Our goal is to reduce our water intensity usage by 20% by 2030. By monitoring and measuring, we gain insights into our water usage. This enables us to find opportunities for improvement, including new conservation measures.

m3 municipal water supply

m3 groundwater

m3 total water withdrawal

*All of our data has been Third-Party Assured (limited assurance). To see our Independent Assurance Statement, click here: AMP-Independent-Assurance-Statement-2024

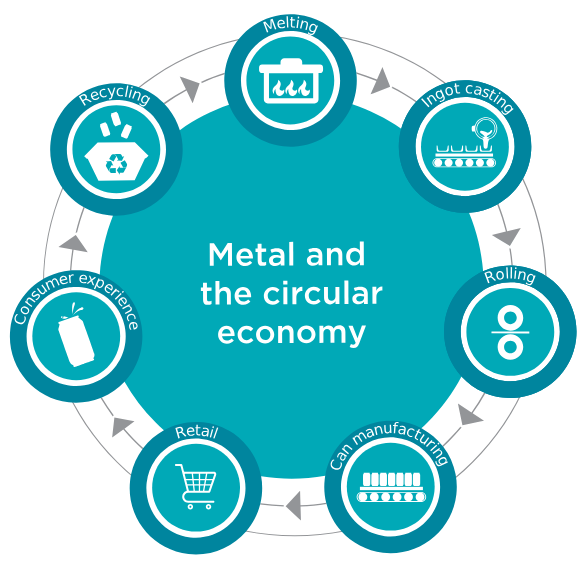

Aluminium can play a vital role in enabling a circular economy, reducing emissions and waste. Recycling aluminium avoids 95% of the energy and emissions generated from producing virgin metal. With a high raw material value and their relative simplicity to recycle, when collected and processed, metal beverage cans contribute to a sustainable, closed-loop system. Promoting industry-wide recycling and the use of recycled content represents a critical factor in the achievement of our Scope 3 GHG emissions reduction targets.

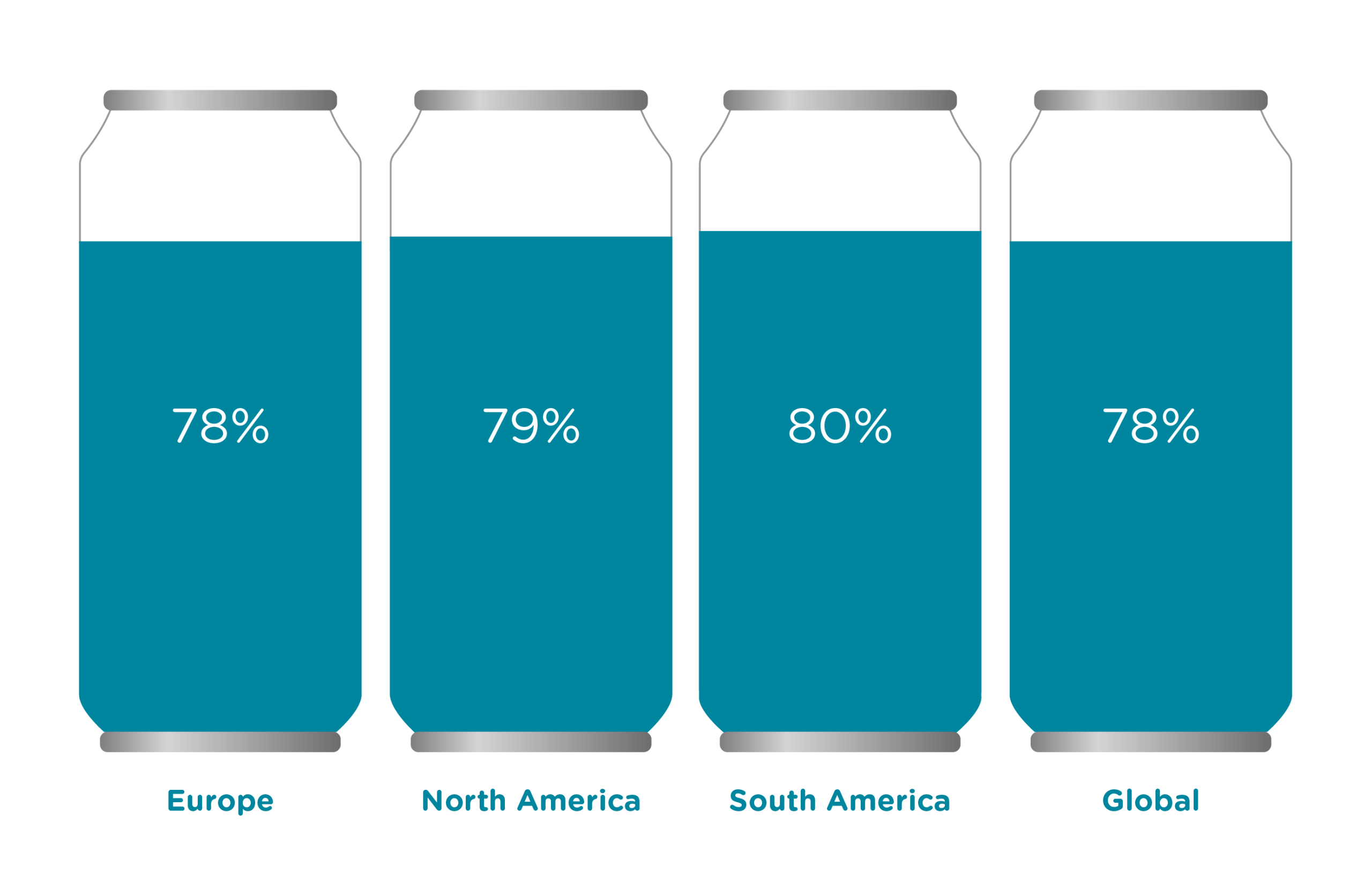

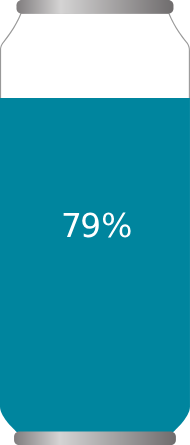

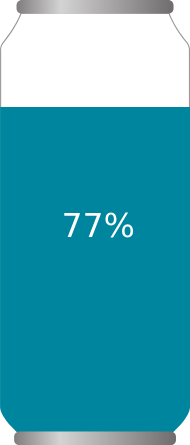

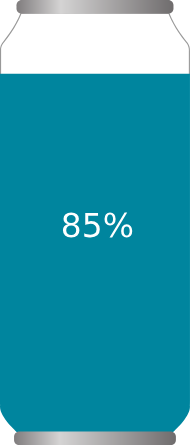

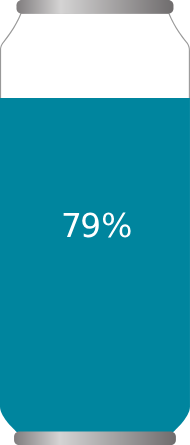

Achieving global decarbonisation requires industry-wide action. To drive an increase in the recycled content in our products, we partner with both suppliers and customers. Together, we’ve identified several strategic initiatives to lower emissions. These include reducing material usage, lightweighting aluminium without compromising quality and optimising logistics to lower fuel consumption. Our procurement strategy and collaboration with suppliers have helped us to achieve a high recycled aluminium content in our beverage cans – an average of 78% in 2024.

Europe

North America

South America

Global

Note: Industry has aligned on a definition of recycled content, which will standardise how the recycled content % is calculated. Data for 2024 onwards will be based on the new industry aligned Beverage Can Recycled Content (BCRC) methodology.

*All of our data has been Third-Party Assured (limited assurance). To see our Independent Assurance Statement, click here: AMP-Independent-Assurance-Statement-2024